Factory Price 1050 3003 Aluminium Plate Amanani

Imodi yokusebenza yomshini wokushisela we-fiber laser ophethwe ngesandla, i-welding ebanjwe ngesandla iyaguquguquka futhi ilula, futhi ibanga lokushisela lide. Ukusebenzisa isibhamu esiphathwayo sokushisela esikhundleni somzila wokukhanya omisiwe wangaphambili kunezinzuzo zokusebenza okulula, ama-welding seams amahle, isivinini se-welding esisheshayo futhi akukho consumables.Ngokushisela amapuleti amancane ensimbi engagqwali, amapuleti ensimbi, amapuleti ama-galvanized kanye nezinye izinto zensimbi, ingakwazi ukufaka esikhundleni ngokuphelele i-argon arc welding yendabuko, i-welding kagesi nezinye izinqubo. Umshini wokushisela we-laser ophethwe ngesandla usetshenziselwa ikakhulukazi ukushisela i-laser yezindawo ezikude nezinkulu zokusebenza.

Indawo ethinteke ngokushisa incane ngesikhathi sokushisela, futhi ngeke ibangele ukuguqulwa komsebenzi, i-blackening, kanye nemikhondo ngemuva. Ukujula kwe-welding kukhulu, i-welding iqinile, futhi ukuncibilika kwanele. Akukho ukubobokeka engxenyeni eyi-convex yezinto ezincibilikisiwe echibini elincibilikayo kanye ne-substrate.Umshini wokushisela we-laser we-Handheld Fiber umshini wokushisela we-laser ohlanganisa imishayo ye-laser yamandla aphezulu ku-fiber optical, ngemva kokudluliswa kwebanga elide, bese iguqulwa ibe amalambu ahambisanayo ngesibuko esihlanganisayo ukuze sigxiliswe kucezu lomsebenzi. Izindlela zokushisela zihlanganisa i-vertical welding, i-paraller welding, i-stitch welding nokunye.

Izici

1. Isivinini sokushisela esisheshayo, izikhathi ezi-2 ~ 10 ngokushesha kune-welding yendabuko.

2. I-weld seam incane, ukujula kokungena kukhulu, i-taper incane, ukunemba kuphakeme, ukubukeka kushelelezi, kuyisicaba futhi kuhle.

3. Inani le-thermal deformation lincane, futhi indawo yokuncibilika kanye nendawo ethintekile ukushisa incane futhi ijulile.

4. Izinga lokupholisa eliphezulu, elingashisela isakhiwo esihle sokushisela kanye nokusebenza kahle kwamalunga.

5. I-laser welding inezinto ezincane ezisetshenziswayo nempilo ende yenkonzo.

6. Ukusebenza okulula akudingi ukuqeqeshwa, kuhambisana nemvelo.

Isicelo

I-laser welding ingasetshenziswa ekushiseni insimbi engagqwali, i-aluminium, ithusi, i-chromium, i-nickel, i-titanium nezinye izinsimbi noma ama-alloys, ingasetshenziswa futhi ezinhlobonhlobo ze-welding phakathi kwezinto ezihlukahlukene, njenge: ithusi - ithusi, i-titanium - igolide, i-Titanium - i-molybdenum, i-nickel - ithusi nokunye.

Amapharamitha

| Imodeli | I-BEC-HW1000 |

| I-Laser Wavelength | 1080 nm± 5 |

| Uhlobo lweLaser | Umfutho oqhubekayo |

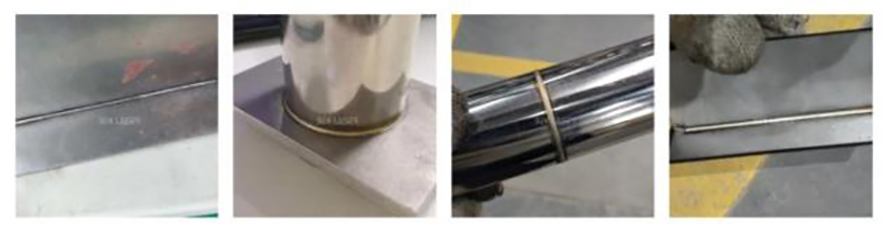

Amasampula

Isibonisi somkhiqizo